Company

Technology and Innovation

Research is a fundamental part of our work.

The R&D department has the latest technologies, such as the R.O.S. Platform, to design solutions one step further in the future.

Modern machinery, demo areas and automatic warehouses ensure just-in-time production.

We adopt the modern methods of lean manufacturing according to the philosophy “the complete elimination of all waste”.

Strategy

History

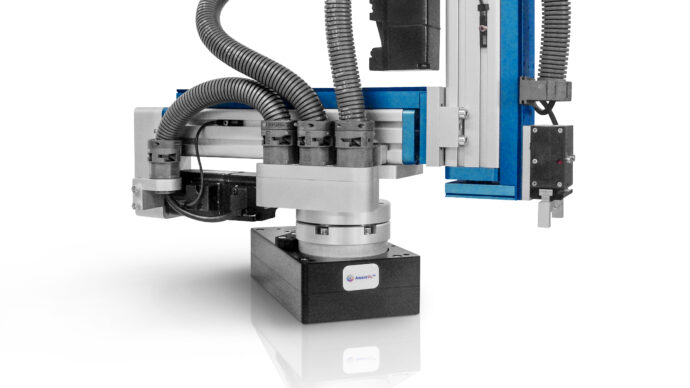

Automationware was founded as a manufacturer of electric actuators, designed to guarantee not only energy savings, but also maximum precision and reliability.

Since then, commitment, determination and constant research activities have led in a short time the company to establish itself as a major player in providing integrated mechatronic products and solutions.

Applications

-

Packaging, food, pharma, medical diagnostic Machinery

Food preparations , drug manufacturing and packaging are mainly areas with great attention to electric actuators and collaborative robotics. Hygiene, flexibility, energy savings associated with precision and reliability are a primary asset for these applications.

Applications of Pick & Place systems • Blistering machines • Filling machines • Filler wrapping machines • Cartesian plotters for packaging and many other applications.

-

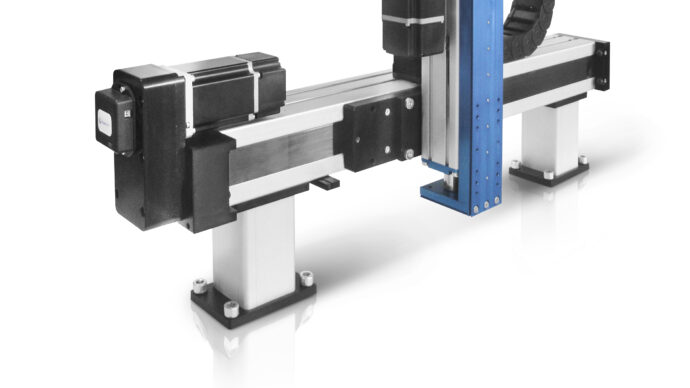

Logistic and Storage system

AW is a leader in the management of Cartesian systems for logistics, also with multiple vertical axes for e-commerce or for vending machines vs. food and pharma segments.

Modularity, may be be used in various applications, also with storage lengths greater than 10 meters with heavy payloads or been used to supply 7 robotic axes where the movement of materials requires a robust structure, maintaining great precision and longevity.

Applications: Mini loads (light load storage systems) • Automatic warehouses (robot warehouses) • Robot axes on logistic or CNC applications (Roboline series)

-

Industrial, CNC and Automotive

The industrial market requires quality, reliable, flexible and adaptable solutions.

AW offers a range of actuators for interlocking, deformation or bending, with precise and reliable electronic control over time.

Applications: Automotive production lines • Production of tires or parts for brakes • lifters for AGV and lifting systems • test benches for avionics and railways • Sheet metal bending or punching systems • Actuators for movement of laser cutting or welding heads • Production of glasses and actuators for plastic blow molding machines • Robotics for interlocking

-

Energy, Naval, Aerospace and Plants

Actuators for the regulation of turbines, production of wind energy, for the management of nautical or military equipment (steering systems, actuators for military systems) • Steward platforms for flight or navigation simulators • Actuators and Robotics for the production of household appliances • Actuators for foundries and production of metals or plastics • Actuators for spooling wire, textile, nylon.

Advice and technical support

Codesign and production of integrable 3D models

Seeking out the best-performing solutions

Optimizing investment

Supply of complete 3D models

Advantages:

AutomationWare, with its team of technicians that specializes in designing solutions with the customer to generate the greatest possible value added by optimizing investment. Models of the assembled solutions or of panels and consoles that can be integrated into the customer’s design software are also created using 3D CAD systems.

More info on: Automationware.it

Contacts

Via Luciano Cacace, 5-7

30030 Martellago (VE), Italia

Obtain directions

Tel.: + 39 041 51 02 028

Email: info@automationware.it